Introduction: The Impact of Artificial Intelligence (AI) in 3D Industrial Design

In today’s rapidly evolving technological landscape, artificial intelligence (AI) has become a key driver of innovation and efficiency across industries. One of the areas where AI has made a profound impact is in 3D industrial design. From automating complex and repetitive tasks to optimizing product designs and manufacturing processes, AI is pushing the boundaries of creativity and performance. By leveraging intelligent algorithms and generative design tools, designers and engineers can now create more precise, lighter, and optimized 3D models, saving both time and costs while maximizing productivity.

This article explores the role of AI in transforming 3D industrial design, highlighting the advanced tools and technologies that are enabling this shift, and providing examples of global success stories. It also examines the challenges and limitations that come with implementing AI in this field, as well as the future outlook for AI’s role in industrial design. As AI-driven technologies continue to grow, a deeper understanding of their benefits and challenges in 3D design can pave the way for further innovations.

1. Definition of Artificial Intelligence and Its Role in 3D Design

Artificial Intelligence (AI) refers to the simulation of human cognitive processes—such as learning, reasoning, problem-solving, and decision-making—by machines and software. In industrial 3D design, AI helps automate and optimize complex processes, significantly reducing errors and speeding up product development.

By integrating AI into 3D modeling tools, industries can improve efficiency, enhance precision, and minimize repetitive manual tasks. This advanced technology transforms the way designers work, providing smarter solutions and allowing faster iterations. AI-powered systems offer designers predictive insights and intelligent suggestions, enabling them to focus on creative aspects rather than operational challenges.

2. AI-Powered Tools and Software in Industrial 3D Design

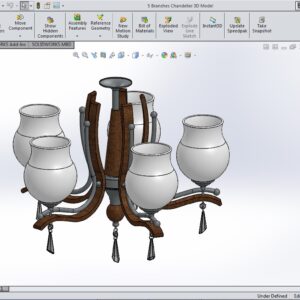

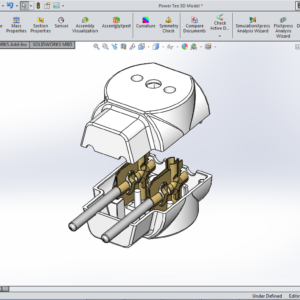

Several advanced 3D design tools now incorporate artificial intelligence to streamline workflows and enhance productivity. These AI-powered software solutions assist designers by automating routine tasks, predicting potential errors, and generating multiple design variations. Here are some leading tools:

– Autodesk Generative Design: This tool uses AI algorithms to create multiple optimized versions of a design based on predefined parameters like weight, material, and durability. It empowers designers to explore innovative solutions that may not be achievable through traditional design methods.

– Fusion 360: Fusion 360 integrates AI and machine learning to offer real-time simulation and error prediction, helping designers detect flaws early in the process and save time during iterations.

– SolidWorks: With AI-enhanced capabilities, SolidWorks helps automate repetitive processes, such as assembly modeling and part configuration, allowing designers to focus on creative problem-solving.

These AI-driven tools revolutionize industrial 3D design by enabling faster prototyping, reducing production costs, and minimizing human error. The software can learn from past projects to improve future outcomes, providing a competitive edge to companies that embrace them.

3. Optimizing 3D Designs with Generative Design Methods

Generative design is one of the most revolutionary applications of artificial intelligence in 3D design. It leverages AI algorithms to explore thousands of design possibilities based on specific parameters, such as material, weight, cost, and structural strength. Unlike traditional design processes, which rely heavily on human input and intuition, generative design allows for data-driven solutions that can significantly enhance product performance.

With AI-powered generative design tools, designers input requirements and constraints—like load capacity or environmental conditions—and the software generates multiple optimized design options. This method allows companies to achieve innovative solutions, reduce material usage, and enhance efficiency.

Key Benefits of Generative Design in 3D Modeling

– Design Efficiency: Generative design speeds up the product development cycle by automatically creating numerous viable design options.

– Material Optimization: AI algorithms help minimize waste by suggesting material-efficient structures, which is especially useful in industries like aerospace and automotive.

– Performance Improvement: Designs generated through AI can meet strict performance standards, offering superior durability or lower weight compared to traditional designs.

Real-World Applications

– Airbus used generative design to create lightweight partitions for aircraft, reducing weight and improving fuel efficiency.

– General Motors applied this method to develop automotive parts that were both lighter and stronger than conventionally designed components.

Generative design allows companies to push the boundaries of innovation by exploring solutions beyond human imagination. This approach not only accelerates design processes but also ensures that the final product is both cost-effective and high-performing.

4. Automating Repetitive Tasks in 3D Design with AI

Artificial intelligence plays a key role in **automating repetitive tasks** in 3D design, freeing up designers to focus on creativity and problem-solving. In traditional workflows, processes such as **rendering, part configuration, and simulation** can be time-consuming and prone to human error. AI-powered solutions streamline these operations, ensuring faster project completion and improved accuracy.

Examples of AI-Driven Automation in 3D Design

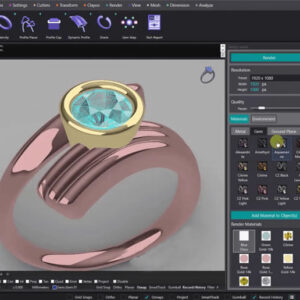

– Rendering Automation: AI-enhanced rendering tools quickly generate photorealistic visuals, enabling designers to test materials, lighting, and environments without manual adjustments.

– Parametric Modeling: AI-based parametric design tools automate the generation of multiple design variations by adjusting predefined parameters, such as size or geometry.

– Error Prediction and Correction: Intelligent systems can identify potential issues—such as structural weaknesses—early in the design phase, suggesting fixes before the prototype stage.

Key Benefits of Automating 3D Design Processes

– Time Savings: Designers can focus more on conceptual and creative tasks while the software handles time-intensive technical operations.

– Consistency and Precision: Automation ensures that repetitive processes are carried out with high precision, reducing inconsistencies.

– Lower Production Costs: Faster project completion leads to reduced labor costs and more efficient use of resources.

Real-Life Applications

– Architecture firms use AI to automate complex building simulations and environmental impact analyses.

– Manufacturers rely on AI-powered CAD tools to automate assembly line modeling and part optimization, leading to faster product launches.

AI-powered automation ensures that 3D design processes are more efficient and less error-prone, helping industries meet tight deadlines without compromising on quality. This shift toward automated workflows enables companies to maintain a competitive edge by speeding up prototyping and production cycles.

5. Reducing Errors and Enhancing Precision in 3D Design with AI

One of the key advantages of incorporating AI into industrial 3D design is the ability to minimize errors and enhance precision throughout the design and production process. In traditional design workflows, human oversight or unexpected complexities can result in costly mistakes. However, AI-powered tools provide predictive insights and automated checks, ensuring higher accuracy from the initial design phase to final production.

How AI Reduces Errors in 3D Design

– Real-Time Error Detection: AI tools integrated into CAD software can identify potential design flaws—such as structural weaknesses or material mismatches—before production begins.

– Predictive Maintenance: AI algorithms monitor the health of design models and tools, predicting when certain components might fail, preventing unexpected breakdowns.

– Design Rule Validation: AI ensures that 3D models comply with industry standards and design rules, reducing the need for manual reviews and rework.

Enhancing Precision with AI-Driven Simulation and Testing

AI-powered simulations enable designers to test multiple scenarios—such as stress tests, fluid dynamics, and temperature resistance—within the virtual environment. This not only improves accuracy but also reduces the dependency on physical prototypes.

– Digital Twins: By creating a digital twin—an exact virtual replica of a product or system—AI allows designers to identify and resolve issues long before production begins.

– Smart Manufacturing Integration: AI ensures the seamless transfer of 3D models into manufacturing, preventing inconsistencies between design and production phases.

Benefits of AI-Enhanced Accuracy in 3D Design

– Lower Production Costs: Fewer errors mean less wasted material and time spent on rework.

– Improved Product Quality: Designs created with high precision perform better and meet stricter quality standards.

– Faster Time-to-Market: Reducing errors in the early design phases ensures faster transitions to production.

AI’s role in error reduction and precision enhancement makes it a critical asset for industries like automotive, aerospace, and healthcare, where even minor flaws can have significant consequences. This data-driven approach ensures high-quality outcomes while saving time and resources.

6. Successful Examples of AI in Industrial 3D Design

Artificial intelligence (AI) has proven to be a transformative force in industrial 3D design, with numerous companies successfully leveraging AI-powered tools to optimize their design processes. Below are some notable examples of how AI is being used to enhance efficiency, creativity, and innovation in industrial design:

1. Airbus: Lightweight Aircraft Components with Generative Design

Airbus, a global leader in aerospace, has utilized AI-driven generative design tools to create lighter and stronger components for their aircraft. Using Autodesk’s Generative Design software, Airbus has been able to explore a vast number of design options in a fraction of the time it would take using traditional methods. This has resulted in the development of components that reduce overall weight, improving fuel efficiency and reducing carbon emissions.

2. General Motors (GM): Redesigning Automotive Parts

General Motors has successfully implemented AI in the redesign of vehicle components. By applying generative design through AI algorithms, GM has developed lighter, more efficient parts that not only reduce material costs but also enhance the performance of their vehicles. For example, GM’s redesign of a seatbelt bracket led to a significant weight reduction while maintaining the required safety standards.

3. Siemens: AI-Powered Digital Twin Technology

Siemens has adopted Digital Twin technology, which combines 3D design with AI to simulate and optimize manufacturing processes. AI helps create virtual replicas of physical systems, allowing engineers to predict performance and detect potential issues before they occur. This integration of AI with 3D design helps companies like Siemens reduce time-to-market and ensure higher-quality products.

4. Nike: Streamlining Footwear Design

Nike has been using AI to revolutionize its footwear design. Through AI-powered design tools, Nike can generate multiple design iterations quickly, enabling the company to experiment with innovative shapes, materials, and structures. These AI systems analyze large datasets of previous designs and customer preferences to create optimized products that meet both functional and aesthetic requirements.

5. Boeing: Enhancing Aircraft Design and Production

Boeing has embraced AI in its design and manufacturing processes, using machine learning algorithms to improve the aerodynamics of aircraft components. AI allows Boeing to automate repetitive tasks, optimize material usage, and create advanced designs that meet stringent safety and performance standards. These improvements have contributed to the company’s ability to produce more efficient aircraft with reduced production costs.

Key Takeaways

These examples illustrate the significant impact of AI on industrial 3D design, from reducing material usage and production costs to enhancing innovation and product performance. Companies across various industries, such as aerospace, automotive, and consumer goods, are increasingly adopting AI-powered design tools to stay competitive and drive technological advancements.

By incorporating AI, businesses can unlock new levels of creativity and efficiency, making it an essential technology for the future of industrial 3D design.

7. Challenges and Limitations of AI in 3D Industrial Design

While artificial intelligence (AI) has greatly advanced 3D industrial design, its implementation comes with notable challenges and limitations. Below are some of the primary obstacles businesses face when adopting AI-driven design solutions:

1. High Implementation Costs

Adopting AI technologies often involves significant financial investment. This includes the cost of advanced AI tools, such as generative design software, as well as the necessary hardware infrastructure. Additionally, the cost of training personnel to work with these new technologies can be prohibitive, especially for smaller businesses.

2. Data Dependency and Quality Issues

AI systems rely heavily on large volumes of high-quality data to generate accurate designs. Poor-quality or incomplete data can lead to suboptimal or flawed designs. Ensuring access to clean, structured data can be time-consuming and resource-intensive for companies, and is often a bottleneck in effective AI adoption.

3. Steep Learning Curve

The introduction of AI into traditional design processes requires significant upskilling of the workforce. Designers and engineers need specialized training to effectively use AI tools, interpret outputs, and apply them in real-world applications. The steep learning curve can slow down the initial implementation, especially for teams with limited AI experience.

4. Ethical and Regulatory Concerns

AI-driven automation in industrial design raises ethical issues, such as the potential for job displacement as more design tasks become automated. Additionally, in industries like aerospace and automotive, there are strict regulatory standards for design and safety, which may limit how AI-generated designs can be used without extensive validation.

5. Limited Human Creativity and Intuition

Although AI is excellent at optimizing designs based on given inputs, it lacks the creativity and problem-solving intuition that human designers possess. While AI can propose numerous design alternatives, it may struggle to innovate in ways that go beyond its data-driven algorithms. Therefore, AI should be viewed as a tool to support, rather than replace, human designers.

6. Algorithm Reliability and Accuracy

The success of AI in generating high-quality designs depends on the accuracy of the algorithms and machine learning models it uses. Any errors in the models can result in flawed designs that may not meet industry standards, especially in fields where safety and precision are critical, such as aerospace and healthcare.

Addressing the Challenges

To overcome these limitations, businesses must take a strategic approach. Investing in the right infrastructure, providing comprehensive training for employees, and ensuring high-quality data inputs are essential steps. Additionally, combining human creativity with AI-driven optimization can lead to more innovative and efficient design processes.

8. The Future of AI in 3D Industrial Design

As artificial intelligence (AI) continues to evolve, its impact on 3D industrial design is expected to grow significantly. Innovations in AI-powered tools and methodologies promise to further transform how products are designed, prototyped, and manufactured. Here are some key trends and future developments that will shape the future of AI in 3D industrial design:

1. Integration of AI with Digital Twin Technology

One of the most promising future trends is the integration of AI with **Digital Twin** technology. Digital twins are virtual replicas of physical systems, such as machines, products, or entire manufacturing processes. By combining AI with 3D design and digital twins, companies can simulate and optimize product performance in real-time, predict potential failures, and improve efficiency throughout the product lifecycle.

For instance, an AI-powered digital twin could continuously monitor the operation of a factory, analyzing vast amounts of data to recommend design adjustments or process optimizations. This integration can lead to better decision-making, faster design iterations, and a more agile manufacturing process.

2. AI-Driven Personalization in Mass Production

In the future, AI will enable greater personalization in mass production through 3D design. Instead of designing products with a “one-size-fits-all” approach, AI algorithms will allow companies to tailor products to individual customer needs while maintaining the efficiency of mass production. By analyzing customer preferences, behavior, and data, AI can generate personalized design options, enabling manufacturers to deliver customized products at scale.

This trend is already seen in industries like footwear, where companies like Nike are using AI to create shoes tailored to the unique foot structure of each customer. The same principle could be applied across various sectors, from automotive to consumer electronics.

3. Fully Autonomous AI Design Systems

As AI technology matures, we may see the rise of **fully autonomous AI design systems** capable of handling the entire design process—from initial concept to final prototype—without human intervention. These systems would use AI to generate, evaluate, and refine designs, optimizing for performance, cost, and materials while adhering to specific engineering constraints.

While humans will still play a critical role in setting goals and reviewing the final designs, the AI could handle most of the iterative and time-consuming aspects of the design process. This shift could significantly reduce time-to-market for new products and free up human designers for more creative and strategic tasks.

4. AI in Sustainable Design and Circular Economy

Another future trend is the increasing use of AI in **sustainable design**. With growing pressure on industries to reduce waste, lower carbon emissions, and adopt circular economy principles, AI can play a vital role in optimizing 3D designs for sustainability. AI can analyze the environmental impact of different materials, suggest eco-friendly alternatives, and generate designs that minimize waste during production.

For example, AI could be used to optimize designs for 3D printing, reducing the amount of raw materials required or enabling the reuse of materials from previous products. This approach aligns with the growing demand for sustainability in industries like fashion, automotive, and consumer goods.

5. Augmented Reality (AR) and AI Collaboration in Design

The future of AI in 3D industrial design may also involve the collaboration between AI and **augmented reality (AR)**. AR allows designers to visualize AI-generated 3D models in real-world environments, making it easier to assess how a design will look and function in its intended setting. Combining AI’s computational power with AR’s immersive visualization can lead to more intuitive design processes, improving the interaction between human designers and AI tools.

6. AI-Powered Collaborative Design Platforms

As industries become more interconnected, the future may bring about **AI-powered collaborative design platforms**. These platforms would allow multiple teams, often spread across different geographical locations, to work on the same design project in real-time. AI would facilitate collaboration by analyzing contributions from various team members, identifying the best design solutions, and offering insights to optimize the overall design.

This type of platform could also enhance communication between designers, engineers, and manufacturers, creating a more seamless transition from design to production.

The future of AI in 3D industrial design holds exciting possibilities. From autonomous design systems to personalized production and sustainable design, AI will continue to shape the way industries develop new products. By staying ahead of these trends, businesses can unlock new levels of efficiency, creativity, and innovation in their design processes, positioning themselves for success in an increasingly competitive market.